Why the Super MAX Works

Improvements to the Super MAX Rigid and Pivoting Arm anchors have been made since their introduction into the market.

- The steel used in the fluke and shank has been strengthened to high-tensile strength tool-grade steel. The use of this grade of steel has resulted in no reports of shank or fluke bending or breaking. The Super MAX is the only anchor in the market using this strength of steel.

- The center of balance of both the Rigid Anchor and the Pivoting Arm Anchor has been moved closer to the leading edge of the outside fluke. When the anchor rests on the seabed (prior to setting), if it does not rest directly on the center fluke tine, it will fall to one side or the other. The back end (the area opposite the point of initial insertion) has been modified to allow the outside fluke tine to penetrate easier into the seabed. (figure 1)

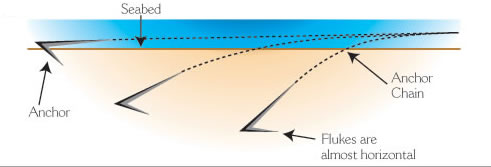

- When the anchor rests on its side on the seabed, it’s weight is on the outside edge point of the fluke. With the anchor in this position on its side, the entire weight of the anchor is resting on the anchor rode shackle at the end of the shank and the edge point of the outside fluke tine. As the chain or rode is pulled in setting the anchor, the shank is lifted off the bottom. When that occurs, the weight of the anchor is entirely on that one outside fluke point and the anchor digs in immediately. The anchor then turns upright as it is pulled and all three flukes dig in to the seabed. In comparison, a plow anchor’s leading edge is blunt and its weight allows it to slide over the bottom rather than dig into the bottom (figure 2).

Figure 1

Figure 2

- The center fluke tine has been modified and, after the anchor rotates to a more upright position, the center tine can better penetrate into hard seabeds. (figure 3)

- The Super MAX has a larger concave shape fluke area translating into increased HOLDING POWER (figure 3). In comparison, a plow anchor has much less surface area, reducing holding power (figure 4).

Figure 3

Figure 4

- The angle of attack for the Super MAX Rigid Shank anchor has been set for greater penetration into all seabeds (figure 5).

Figure 5

With all of these improvements, our own tests reveal the Super MAX Rigid anchor’s penetration into all seabeds increased immeasurably. We have tested the Super MAX Rigid against a spade anchor and found it to be much quicker to set and its holding far exceeds that of the spade. Tests carried out by independent boat owners reveal that the Super MAX anchor works in all types of bottoms. Other anchors frequently rotate out of the bottom when they become overloaded. The Super MAX anchor creeps forward a little then digs deeper, toward harder bottom material creating greater holding power.

Owners of Super MAX anchors have told us there isn’t a better anchor made. They tell us how it always sets the first time and about its remarkable holding power in hurricane strength winds. Owners state, “The best thing about a Super MAX anchor is that it works in all bottoms – without fail. From grass to coral and all the normal bottoms, Super MAX anchors grab in any seabed”. The best part about using a Super MAX anchor is that boat owners and crew sleep well at night when anchored.

Setting technique:

In order for any anchor to perform to its maximum potential and design, it must be set properly using the manufacturers directions. After properly setting the Super MAX Anchor, you can be sure that your boat is being held by the strongest, most firmly holding anchor in the world. We believe the Super MAX Anchor is the best design for maximum holding power of any anchor in the industry.

- After checking the area for the optimal location to anchor, add the height from the water surface level to bow roller to the depth of water. That is your actual depth for anchoring.

- Bring your vessel to a complete stop. Lay out the length of chain/rode from seabed floor to bow roller and allow the anchor to settle into the seabed.

- As the boat gently settles backwards play out the rode to a 2 1/2 to 3 to 1 scope. Take your time and allow the boat to ease backward slightly so that chain does not lay on the anchor. Allow the anchor to settle into the seabed by its weight alone. Do not rush.

- Once the chain begins to straighten, the anchor is digging into the seabed. Secure the chain to protect the windless and slowly increase the RPM of the engine to pull tight and set the anchor. Continue to increase the RPMs to firmly set the anchor in the seabed.

- Lay out about a 5 to 1 scope and repeat the process, backing down slowly. As the chain straightens again, secure the chain to protect the windless and increase the RPMs until the anchor set causes the boat to jerk to a stop again.

- You are firmly set in the seabed. Lay out the desired rode length.

When determining anchor rode scope, consider tidal changes, potential wind shifts or increase in velocity, proximity to other boats and land structures, and predicted weather conditions. Under normal conditions the following scope ratios are recommended.

Rigid Shank Super MAX Anchors,

Sand, hard mud, and coral use a 4:1 scope- Mud, increase the scope to at least 6:1.

- Ooze or very soft mud, increase the scope to at least 8:1.

- If all chain rodes are used, scopes may be reduced to 3:1, 5:1, and 7:1 respectively from the above settings.

Pivoting Shank Super MAX Anchors (the fluke to shank angle to the type of seabed)

- Sand, hard mud, and coral use a 5:1 scope and the lowest hole adjustment (smallest fluke/shank angle)

- Mud, use a 5:1 scope and the middle hole adjustment

- Ooze or very soft mud use a 5:1 scope and the highest hole adjustment (largest fluke/shank angle)

- In tight anchorages, using an all chain rode, you may move the setting to a more open position and reduce the scope to 4:1.

As is the case with most anchors, if for some reason the anchor breaks free from the set, it will not re-set in scopes greater than 5:1. If the scope is greater than 5:1, you must reduce the scope to at least that ratio in order to have the anchor re-set.

Holding Performance

Anchoring in protected waters is desired, however, Super MAX Anchors are designed to securely hold in less than optimal conditions.

- Super MAX Anchors are oversized for the gross weight of the vessel they are recommended for. In anchoring, bigger is better!

- Super MAX Anchors are designed for the strongest of winds. There are many documented examples of Super MAX Anchors being deployed in hurricanes (winds in excess of 71 miles per hour). To our knowledge, there has never been a time when a Super MAX Anchor has bent, broken, or dislodged from its setting during any of these hurricanes. Holding in wind velocities of this magnitude requires additional scope on the rode but the Super MAX will hold.

- Super MAX Anchors are designed to hold when there is an expectation of wind sheer and current/tide changes. In addition, the Super MAX Anchor will hold in large open areas of unprotected waters. The steel in a Super MAX Anchor is the strongest in the anchoring industry.

Retrieval Techniques:

The Super MAX Anchor is designed to dig deep into the seabed for maximum holding. Use the vessel’s engine as you retrieve the anchor rode and reduce the scope. Using the windlass to pull the vessel to the anchor setting point in the seabed places undue stress and wear on the windlass motor. As the anchor rode is retrieved and the tension increases, snub the rode and use the vessel’s engine to pull the anchor free. Once on top of the anchor setting position, if the anchor is still secure, with the rode straight up and down, secure the rode and back down using the vessel’s engine.

Another option is to use the trip line lug on the back of the anchor shank. When deploying the anchor, attach a trip line to the lug and run approximately 50′ of line up the anchor rode, leaving about 5′ slack. Tie the trip line to the chain or rode using a rolling hitch. Once the rolling hitch is brought to the bow roller, untie the rolling hitch and continue to retrieve both the rode and the trip line. If the anchor is resisting breaking free using the anchor rode, pull in the trip line to allow the anchor to withdraw from the seabed opposite from the direction of setting. Once free, continue to retrieve both the chain/rode and the trip line.

Once the anchor is free from the seabed, drag the anchor about 1-2 feet below the surface at slow speed to remove most of the sediment. Because the Super MAX Anchor digs deep and depending on the quality of the seabed, you may pull a great deal of seabed up when retrieving the anchor.

Remember, the Super MAX Anchor looks BOLD for the STRONGEST HOLD.